Grand Haven, MI – Shape Corp. was named a GM Innovation Award winner during a virtual ceremony to celebrate the recipients of General Motors’ 28th annual Supplier of the Year awards on Wednesday, June 24. GM’s Innovation Award recognizes the top suppliers among thousands of global contenders that introduced innovations that deliver cutting-edge technologies that substantially enhance vehicle capabilities and/or customer experience. Shape Corp. was named one of four 2019 Innovation Award winners for the innovative carbon fiber pultruded rear bumper beam featured on the 2020 Corvette Stingray. “The GM Innovation Award represents the years of hardwork and determination put forth by our collective teams to push the envelope with carbon […]

Shape Corp., a tier one automotive supplier was awarded a 2020 Automotive News PACE (Premier Automotive Supplier’s Contribution to Excellence) Innovation Partnership Award in conjunction with General Motors for their collaboration in engineering and manufacturing the automotive industry’s first curved, multi-hollow pultruded carbon fiber bumper beam for the 2020 Chevrolet Corvette Stingray. The Innovation Partnership Award was presented virtually to Shape Corp. and General Motors during the 26th annual PACE awards ceremony held on Tuesday, April 28, 2020, recognizing the collaborative effort between General Motors and Shape when defining innovative and cost effective ways to continuously produce the carbon fiber beam for its vehicle application. “Developing innovations through partnerships is […]

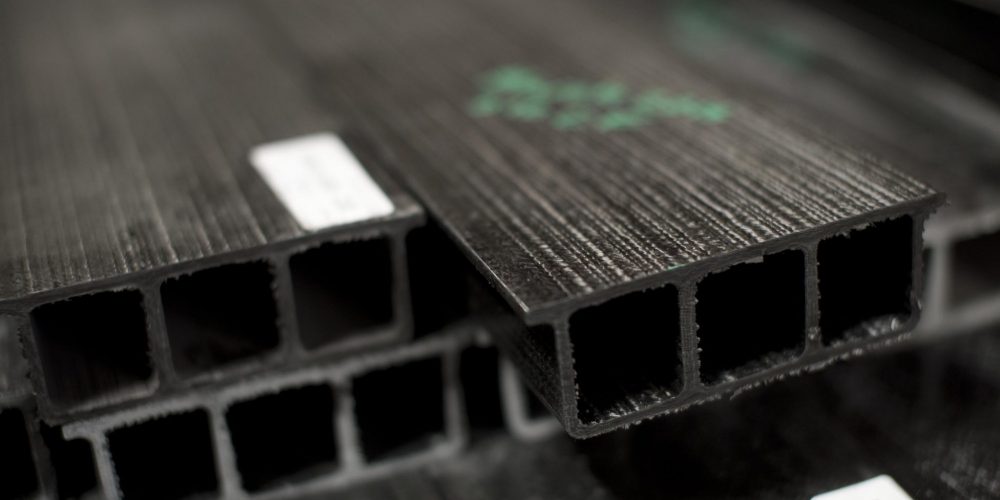

Pultrusion is one of the most cost-effective processes for manufacturing high-volume composite parts. Recently Composites World featured Shape Corp’s recent composites advancements as an example of the growth composites are experiencing in the automotive market place. To read the full article click here.

Applications for carbon fiber in a vehicle’s body structure continue to gain positive momentum, with BMW’s i3 being a prime example. Advancements are being made throughout the industry and the case for carbon fiber is becoming more viable. Learn more by reading a recent article from Automotive Manufacturing Solutions. Read more…

Finding a consensus on the most important type of mechanical test for composites can be a difficult task, especially with the variety of applications composites are being used for. Composites World columnist Dr. Dan Adams, explores this topic in a recent article. Read more…

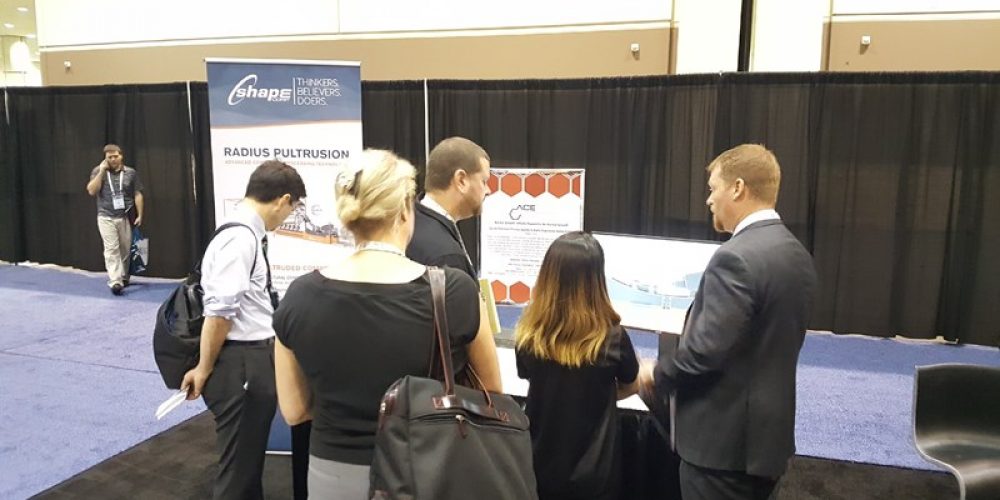

Shape’s innovative spirit was on display at the 2017 CAMX—the premier composites and advanced materials event and for four days the center of the composites world. Shape was in attendance as a finalist for an Award for Composite Excellence (ACE), the composite industry’s stand out award showcase. The ACE awards are an annual competition hosted by the American Composites Manufacturers Association (ACMA) that recognizes superiority in engineering and design, as well as improvements and innovation in equipment and manufacturing. Shape was a finalist in the Infinite Possibility for Market Growth category for our use of curved pultrusion to create highly engineered hollow profiles. The award, which was taken home by Ford and Magna […]

Composites Manufacturing Magazine featured some very exciting pultrusion technology Shape is licensing from Thomas Technik + Innovation. You can read more about is creation, development and wide range of applications here.

Shape’s bright future and the innovative radius-pultrusion system are featured in the June edition of Composites World, the world’s leading composites publication. The center fold article profiles Thomas Technik’s curved pultrusion process and features details regarding Shape licensing the technology for use in the automotive industry. While a number of licensees were highlighted in the article, Shape’s relationship and work are prominently covered. You can read the full article here. Shape remains on track to install our first curved pultrusion machine this year, in preparation for 2019 model year production. Be on the lookout for future updates as we bring this new innovative process to Shape.

With the automotive industry heavily focusing on lightweighting for improving fuel economy, Shape as always, is eager to support our customers with innovative, lighter weight components. For years we’ve been developing bumper solutions that are some of the best in the industry, utilizing ultra-high strength steels, unique aluminum alloys, and patented cross section designs. Still the need to do even better continues. Shape is now developing a unique technology to bring carbon fiber bumpers to our customers. Carbon fiber is an extremely lightweight, but expensive material, not traditionally suited for automotive high volume programs and the common car. However, Shape’s roll forming process and design experts have found a way […]