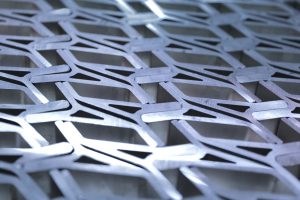

Shape’s advanced extrusion capabilities, powered by our 4,000-ton and two 5,500-ton presses, open up a vast range of size, weight, and tolerance possibilities that set us apart from the competition. With our unmatched flexibility and precision, we extrude profiles from an impressive 16-inch circle size down to intricate 1-inch profiles, all while maintaining the tightest tolerances. Leveraging our expertise in metallurgical alloys, microstructure optimization, and precision tooling, we deliver high-performance, complex profiles tailored to meet the most demanding specifications.

5,500 TON 12″ EXTRUSION PRESS

- Designed to extrude complex multi-void hollows and quench sensitive alloys

- Alloys:6060, 6063, 6061, 6005A, 6008, 6082 and some 7XXX series alloys

- Max Circle Size: 14″

- Max Height: 6″

- Max Width: 13.5″

- Max Weight: 9 lbs/ft

- Unit Pressure at the die face: 91,235 lbs/in2

5,500-TON 14″ EXTRUSION PRESS

- Designed to extrude asymmetric cross sections and quench-sensitive alloys

- Alloys: 6000 series alloys (including quench-sensitive automotive applications)

- Max Circle Size: 13.5”

- Max Height: 6″

- Max Width: 13.5″

- Max Weight: 30lbs/ft (standard, with options for higher)

- Unit Pressure at the die face: 67,787 lbs/in²

4,000-TON 10″ EXTRUSION PRESS

- Designed to extrude asymmetric cross sections and quench-sensitive alloys

- Alloys: 6000 series alloys (including quench-sensitive automotive applications)

- Max Circle Size: 9.5”

- Max Height: 6″

- Max Width: 9.5″

- Max Weight: 25lbs/ft (standard, with options for higher)

- Unit Pressure at the die face: 94,629 lbs/in²

At Shape, our extrusion team harnesses cutting-edge equipment and innovative process techniques to set the standard for excellence in the industry. We have the expertise and the people to consistently deliver high-precision profiles that meet the most demanding dimensional and performance requirements—pushing the boundaries of what’s possible in aluminum extrusions.

Unlike most extruders, we offer complete fabrication and finishing services. Our total control of the entire development process ensures your products achieve peak quality. In addition, our

state-of-the-art CNC machining centers make sure your parts are precision crafted eliminating the need for subcontractors saving company time and money on your next project.

At Shape, our engineering team excels in delivering high-precision, complex extrusions that meet the most demanding specifications in the industry. Our expertise spans across tooling CAE (Computer-Aided Engineering), process engineering, and customized solution development to address our customers’ unique needs.

At Shape, our engineering team excels in delivering high-precision, complex extrusions that meet the most demanding specifications in the industry. Our expertise spans across tooling CAE (Computer-Aided Engineering), process engineering, and customized solution development to address our customers’ unique needs.

Tooling CAE and Simulation Expertise

- Our engineers leverage advanced CAE simulations and close collaboration with leading tool manufacturers to optimize every stage of the extrusion process. By simulating real-world performance, we can anticipate and mitigate challenges early, ensuring that every extrusion meets exacting standards. This results in precision tooling that accommodates tight tolerances and complex profiles.

Process Engineering

- With a deep understanding of metallurgy and process engineering, we can extrude both large and small profiles with precision, from 16-inch to 1-inch circle sizes. We also specialize in extruding quench-sensitive alloys, ensuring optimal mechanical properties and performance for the critical applications used in the automotive industry. Our engineers continually refine and optimize the extrusion process, ensuring efficiency and consistency with each production run.

Customer-Centric Solutions

- Shape provides fully integrated solutions, from the initial design to the final performance testing. We offer the ability to create complex, high-performance profiles, leveraging our microstructure optimization to achieve both recrystallized and fibrous grain structures, tailored to specific performance needs. This allows us to address stringent dimensional and mechanical demands that many other manufacturers cannot meet.

- By combining our engineering expertise with cutting-edge technology and our partnerships with tool manufacturers, we detect and address the slightest performance variances almost instantly. This ensures that we consistently deliver extrusions to our customers at the highest standards, no matter the complexity of the design.

Exceeding standards to make sure our products and services are safe and reliable. We have achieved IATF 16949:2016 Certification – the global automotive standard developed by representatives of all major automotive manufacturers in the world. Given our commitment to environmental stewardship, we have also achieved ISO 14001:2015 Certification.

Exceeding standards to make sure our products and services are safe and reliable. We have achieved IATF 16949:2016 Certification – the global automotive standard developed by representatives of all major automotive manufacturers in the world. Given our commitment to environmental stewardship, we have also achieved ISO 14001:2015 Certification.